CNC turning is a particular form of precision machining in which a cutter removes material by making contact with the spinning work-piece.

CNC Turning

The movement of the machinery is controlled by computer instructions, allowing for extreme precision and repeatability.

Turning is different to CNC milling, in which the cutting tool rotates and is directed from multiple angles at the work-piece, which is usually stationary. Because CNC turning involves rotating the work-piece in a chuck, it is generally used to create round or tubular shapes, achieving far more accurate rounded surfaces than would be possible with CNC milling or other processes.

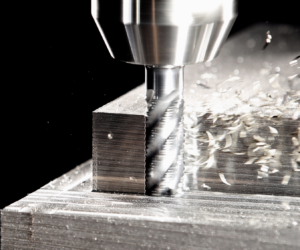

CNC Milling

CNC milling is just one of the CNC machining processes available. Milling is a particular form of precision CNC machining. Milling uses a cutter that removes material by moving into the work-piece at an angle. The movement of the cutter is controlled by computer instructions, allowing for extreme precision and repeatability.

MANUAL TURNING

For the smaller jobs we carry out manual turning as required.